Product

Product  LNG / LPG TANK INSULATION SYSTEM

LNG / LPG TANK INSULATION SYSTEM

DAEHYUP TECH in cooperation with LNT MARINE are offering spray foam insulation systems for various types of cargo/fuel tanks. We supply complete insulation systems including all engineering, material, labor and project management during insulation.

The purpose of the insulation system is to minimize boil off rate by limiting the heat ingress. All with unique properties for use in different environments with different surface materials to optimize the function of the system.

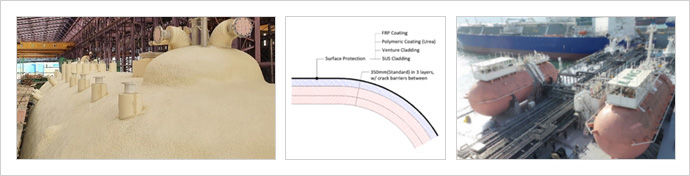

All systems are fully bonded spray foam insulation systems tailor-made and optimized for the client’s needs and have the same basic thermal insulation design based on spray foam insulation with two layers of imbedded crack barriers. The insulation is flexible enough to follow the tanks contraction and expansion. There is no voids and no joints for accumulation of moisture between tank surface and insulation layer.

The Spray Foam System is developed to improve insulation efficiency, minimize maintenance and reduce application time.

The Spray Foam System consists of two types of materials; a polyurethane foam for low temperature insulation, and surface protection materials.

The foam with constant density is sprayed on the tank surface in several layers (<35mm) to build up to the total specified insulation thickness.

Coating is sprayed on the foam surface with a thickness of 3 mm on top of the tank and 1 mm on sides and bottom. Other finishing materials such as GRP and metal cladding can be available.

The spray system is a bonded insulation system with flexible materials. Foam and coating will follow the contraction and expansion of the tank.

The insulation system is designed to fulfil requirements from all the classification societies.

IMO type B LNG tank insulation system (AiP & GApp)- Lloyd’s Register

Material TA (type approval)- Lloyd’s Register

- Russian Maritime Register of Shipping

- Korean Register

- No voids and no joints in the insulation foam

- No space for moisture accumulation

- Homogeneous insulation

- Increased insulation efficiency

- Complete bonding to all surfaces

- Short application time at the ship yard

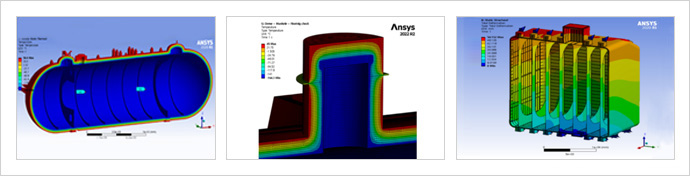

- Finite Element Analyses – Thermal and Structural

- 3D Modeling and concept modeling

- Production drawings

- Physical cryogenic testing

- Insulation system documentation with Class’ approvals

- Heat transfer and boil-off rate calculations